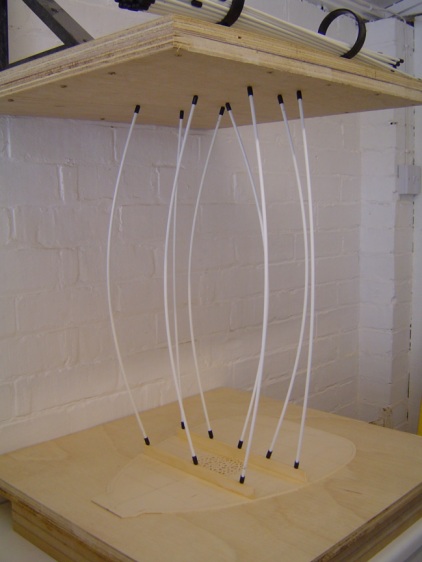

I'm making myself a new go bar deck. I'm thinking of using fiberglass rods from driveway markers (those things with the reflectors on top). Some of you have done that, and that's where I got the idea. So, some questions: once you cut off the reflectors, do you put rubber tips on the rods? If so, where do you get them, or do you make them yourself with that liquid rubber dippy stuff? Any tips on finding and using that stuff if that's how you do it? Is it a piece of cake to cut the fiberglass rods, or are they going to splinter and split on me unless I do it the right way - if so, what's the right way to do it?

The other possibility I'm considering is making rods out of wood. I've only used fiberglass rods. If you've used both fiberglass and wood rods, which would you recommend and why? If you use wood rods and love 'em, what species do you use and how thick do you make them? And finally, I'd be interested to hear how much longer you make the rods than the distance between the decks.

Thanks!

|

One advantage into the Wind does have is true 48" long stock vs the 47 1/4 avrage length of the rods in the driveway reflectors. However if your deck is adjustable in height, then no big deal.

One advantage into the Wind does have is true 48" long stock vs the 47 1/4 avrage length of the rods in the driveway reflectors. However if your deck is adjustable in height, then no big deal.